The Benefits of a Cross Sheeter Dough Flattener

Share this page:

Summary of Key Advantages

INCREASED PRODUCTION EFFICIENCY

Automates the dough flattening process, reducing the time spent on each batch and allowing for higher output.

IMPROVED DOUGH CONSISTENCY

Ensures uniform thickness across every batch, resulting in consistently baked goods and improved product quality.

REDUCED MANUAL LABOR

Significantly cuts down on the manual effort required to flatten the dough, alleviating strain on workers and reducing human error.

ENHANCED PRODUCTION SPEED

Designed to keep up with the fast pace of commercial baking, allowing for continuous operation during peak hours or large orders.

VERSATILE FOR MULTIPLE DOUGH TYPES

Adjustable settings allow for flattening dough types, including pizza, flatbread, and puff pastry.

DURABILITY AND RELIABILITY

Built with long-lasting materials to handle the daily demands of a busy bakery environment.

EASY INTEGRATION

Can be easily integrated into existing production lines without significant changes, making it a convenient upgrade for bakeries.

Maximizing Efficiency and Quality with a Cross Sheeter Dough Flattener

In the fast-paced world of commercial baking, efficiency and consistency are key. Having the right dough preparation equipment can significantly improve your bakery's output when preparing flatbreads, pizzas, or other dough-based products. The cross-sheeter dough flattener is an important tool for bakers looking to increase production speed and improve product quality.

This equipment streamlines the process of flattening dough, creating uniform thickness and reducing the need for manual labor. It is a game-changer for bakeries of all sizes.

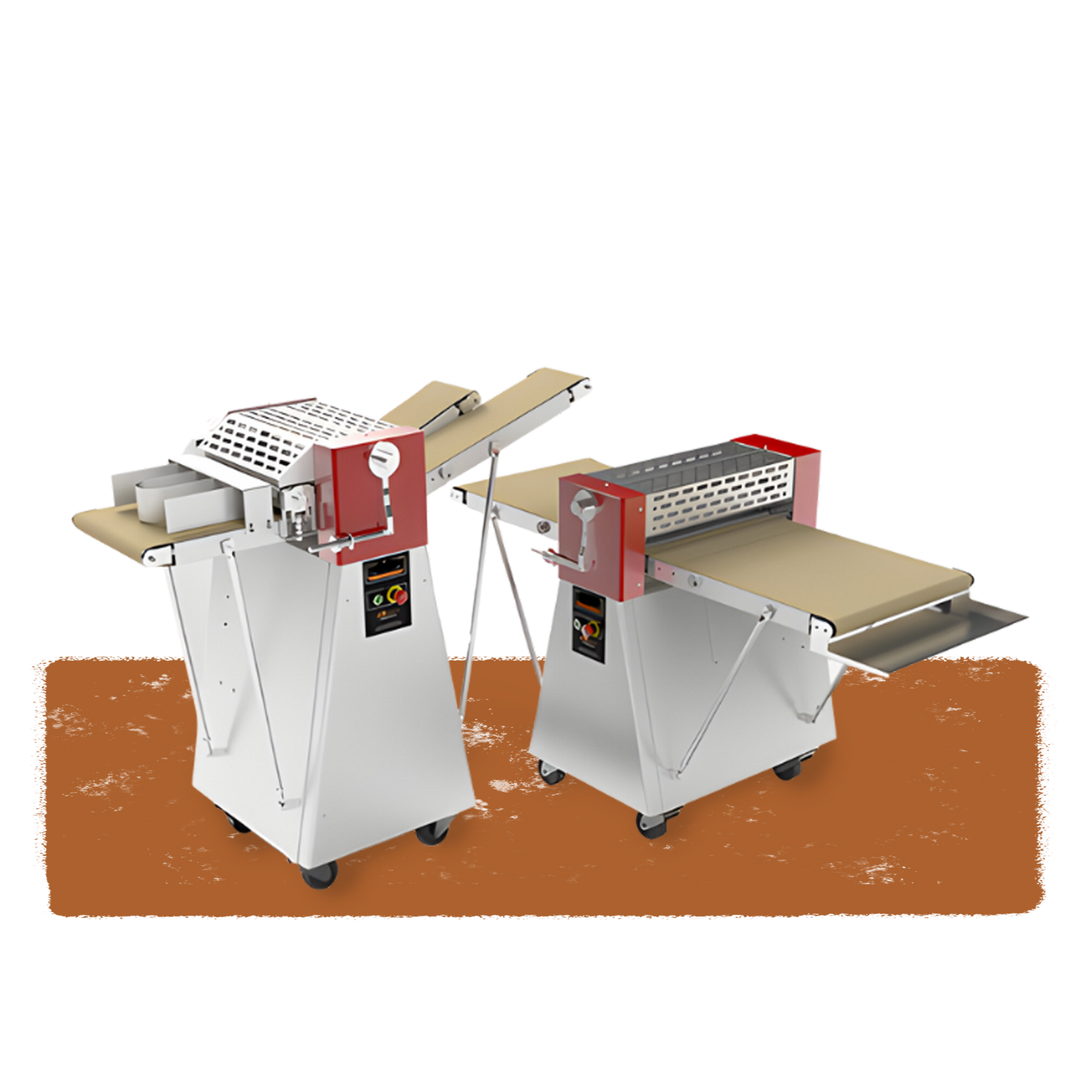

What Is a Cross Sheeter Dough Flattener?

A cross-sheeter dough flattener is specialized equipment designed to flatten dough evenly and efficiently. Unlike traditional methods, where dough flattening relies heavily on manual effort, a cross-sheeter uses rollers and automated systems to create consistently flat dough. This machine passes the dough between two rollers, which presses it into the desired thickness. The cross-sheeting motion, which rolls the dough in multiple directions, helps maintain the dough's integrity, resulting in an even texture and uniform thickness.

For bakery owners or production managers who need a reliable solution for flattening large batches of dough, a cross-sheeter dough flattener can reduce manual work while maintaining the highest quality standards.

Increased Efficiency

One of the most significant advantages of using a cross-sheeter dough flattener is increased production efficiency. When you're managing a high-volume bakery, time is of the essence. Flattening dough by hand can be time-consuming and inconsistent, significantly when scaling up for larger orders. A cross sheeter speeds up the process by automating it, allowing your staff to focus on other tasks.

This dough sheeting machine can quickly handle large amounts of dough, reducing the time spent on each batch and helping you meet production deadlines more efficiently. When you can produce more in less time, it means higher output and, ultimately, higher revenue potential.

IMPROVED DOUGH CONSISTENCY

Inconsistent dough thickness can lead to uneven baking, affecting the quality of your final product. Flatbreads that are too thick in some areas and too thin in others can result in a product that doesn't bake evenly, leaving you with unsatisfactory results.

A cross-sheeter dough flattener eliminates this problem by ensuring uniform thickness across every batch. The cross-sheeting motion guarantees that the dough is evenly flattened, no matter the type of dough you're working with. This means your flatbreads or other baked goods come out perfectly every time, creating a better customer experience and a stronger reputation for your bakery.

REDUCED MANUAL LABOR

Baking is a labor-intensive industry, and any opportunity to reduce manual effort while maintaining quality is worth considering. With a cross sheeter dough flattener, your bakery can significantly reduce the amount of manual labor required to flatten dough.

Without this machine, workers would need to spend time rolling dough by hand, which can be physically demanding and lead to fatigue, especially over long shifts. Automating this part of the process can relieve some of the strain on your employees, helping them focus on other aspects of production or quality control.

Reducing manual labor also means less human error. No matter how skilled your staff is, hand-flattening dough can result in slight variations in thickness. A cross sheeter eliminates this risk, providing consistent results batch after batch.

INCREASED PRODUCTION SPEED

In a busy bakery, every second counts. The cross-sheeter dough flattener is designed to keep up with the fast pace of commercial production. Its automatic dough sheeter system allows you to produce large quantities of flattened dough in a fraction of the time it would take manually.

This bakery sheeter machine allows for continuous operation, meaning you can keep up with demand during peak hours or large orders without sacrificing quality. Producing more dough in less time can help you meet customer expectations, whether running a small local bakery or managing production for a more extensive wholesale operation.

VERSATILITY IN DOUGH TYPES

One of the standout features is its versatility. This machine is not limited to just one type of dough. Whether you're working with pizza dough, flatbread, or puff pastry, the cross sheeter can handle it all.

Different doughs require different thicknesses, and with this equipment, you can easily adjust the settings to meet the specific needs of each product. This flexibility allows you to expand your product offerings and cater to a broader range of customers, whether looking for thin, crispy flatbreads or thicker, chewier pizza bases.

DURABILITY AND RELIABILITY

Investing in a cross-sheeter dough flattener is a smart move for long-term success. These machines are built to last and are designed with durable materials that can withstand the rigors of daily use in a busy bakery environment.

Reliable equipment is crucial for maintaining smooth operations. You want to avoid equipment failure during a large production run. A commercial dough flattener offers consistent performance, giving you peace of mind that your equipment will perform when needed.

ENHANCING DOUGH QUALITY

Another benefit is its ability to enhance your dough quality. This machine helps preserve the dough's natural structure and elasticity by evenly flattening it without overworking it.

Overworking dough during manual flattening can lead to tough, chewy baked goods. The gentle rolling action of the cross sheeter helps avoid this, resulting in light, airy products with the perfect texture.

EASY INTEGRATION INTO YOUR PRODUCTION LINE

If you're worried about how a new piece of equipment might fit into your current setup, you'll be pleased to know that most cross-sheeter dough flatteners are designed for easy integration. They can be incorporated into existing production lines without significant changes, making them a convenient upgrade for bakeries looking to improve efficiency.

Many models are compact and have customizable settings, so you can adjust them to meet the specific needs of your bakery. Whether you need a small machine for a boutique operation or a larger model for a high-volume production line, a dough flattener can fit your requirements.

Is a Cross Sheeter Dough Flattener Right for Your Bakery?

A cross-sheeter dough flattener is an excellent investment if you're looking for a way to streamline your dough preparation process and boost productivity. By automating the dough flattening process, you can increase production speed, improve consistency, and reduce the physical strain on your team. Plus, the versatility of these machines means you can work with a wide variety of dough types, helping you expand your product offerings.

DISCOVER MORE ABOUT HOW THIS EQUIPMENT CAN BENEFIT YOUR BAKERY.

Visit our product page to explore the features and specifications of our cross-sheeter dough flatteners and see how they integrate seamlessly into your production setup.

Share this page:

You May Also Be Interested

Site Map

AMI Equipment

Expertly crafted ovens and automation solutions for authentic, traditional flatbread production. Fully customizable and backed by lifetime support.

Follow Us:

Copyright © 2024 AMI Equipment - All Rights Reserved