Top 10 Essential Pieces of Bakery Equipment for Efficient Flatbread Production

Share this page:

Building the Perfect Flatbread Production Setup

In the world of flatbread production, where tradition meets innovation, having the right bakery automation equipment is crucial for streamlining processes and ensuring consistent, high-quality output. Whether you're crafting Pita, Naan, or Lavash, each step requires precision, and that starts with the right tools.

Every step in the process needs to be performed correctly, and having high-quality equipment in place ensures that you can produce high-quality flatbread time and time again. This guide outlines the top ten essential pieces of bakery equipment you'll need to produce flatbreads efficiently and consistently.

Dough Mixer: The Essential Start for Consistent Flatbread Dough

A dough mixer is the cornerstone of any bakery and is crucial for making flatbread. This machine thoroughly mixes ingredients like flour, water, salt, and yeast to create a uniform dough. Without a reliable dough mixer, achieving consistent quality in flatbreads would be challenging.

When selecting a dough mixer, consider the capacity and the type of dough you'll mix. Spiral mixers are often preferred for flatbreads because they efficiently handle high-hydration doughs. Ensure the mixer can handle continuous operation in a commercial setting.

Bowl Tilting Machine: Simplify Heavy Dough Handling

The next step after mixing is transferring the dough for further processing. A bowl tilting machine allows for the easy and safe transfer of heavy dough from the mixer to other work surfaces or equipment.

It's essential to look for a bowl tilting machine compatible with your dough mixer's bowl size and capacity. Some factors to consider include how easy it is to operate and whether it can handle large batches of dough without spilling.

Dough Divider: Achieve Perfect Portioning Every Time

A dough divider creates consistent portion sizes for each piece of flatbread. This consistency is essential for the baking process and the quality of the final product.

Automatic dough dividers are ideal for high-volume production. They should be adjustable to accommodate different flatbread types, whether you're making Pita, Roti, or Manakish. Ensure the divider you choose can handle the specific dough consistency required for your recipes.

Dough Rounder: Ensure Uniformity for Ideal Dough Texture

After dividing the dough, the pieces need to be rounded into uniform balls to prepare them for the following stages of production. A dough rounder automates this process, saving you time and improving consistency.

Consider a conical rounder for flatbreads, as it is particularly effective for rounding softer doughs like those used for Naan or Gözleme. The machine should be adjustable for different dough weights and types.

Dough Sheeter or Roller: Precision Flattening for Consistent Bakes

The next step in producing flatbread is to flatten the dough balls into their final shape. A dough sheeter or roller should be used to create the thin, even layers required for flatbreads like Lavash or Paratha.

Choose a sheeter with adjustable settings to accommodate various flatbread thicknesses. The roller surfaces should also be non-stick to prevent dough tearing or sticking, which can ruin the final product.

Proofer: Perfect the Rise for Fluffy, Flavorful Flatbreads

A proofer allows the dough to rise before baking. This step is crucial for achieving the flatbreads' right texture and flavor. Proper proofing enhances the softness and elasticity of the dough, which is necessary for products like Focaccia and Pita.

Temperature and humidity control are the most important features to look for in a proofer. Consistent proofing conditions are essential to achieving uniform results across all batches.

Commercial Flatbread Oven: The Final Touch for Even, Efficient Baking

Flatbreads develop their final texture and flavor during the baking process. Commercial ovens, such as tunnel ovens or rotating ovens, are designed to bake flatbreads quickly and evenly.

Based on your production volume and space availability, choose between tunnel ovens and rotating ovens. Tunnel ovens are ideal for large-scale operations while rotating ovens are suitable for bakeries with limited space that still require high efficiency.

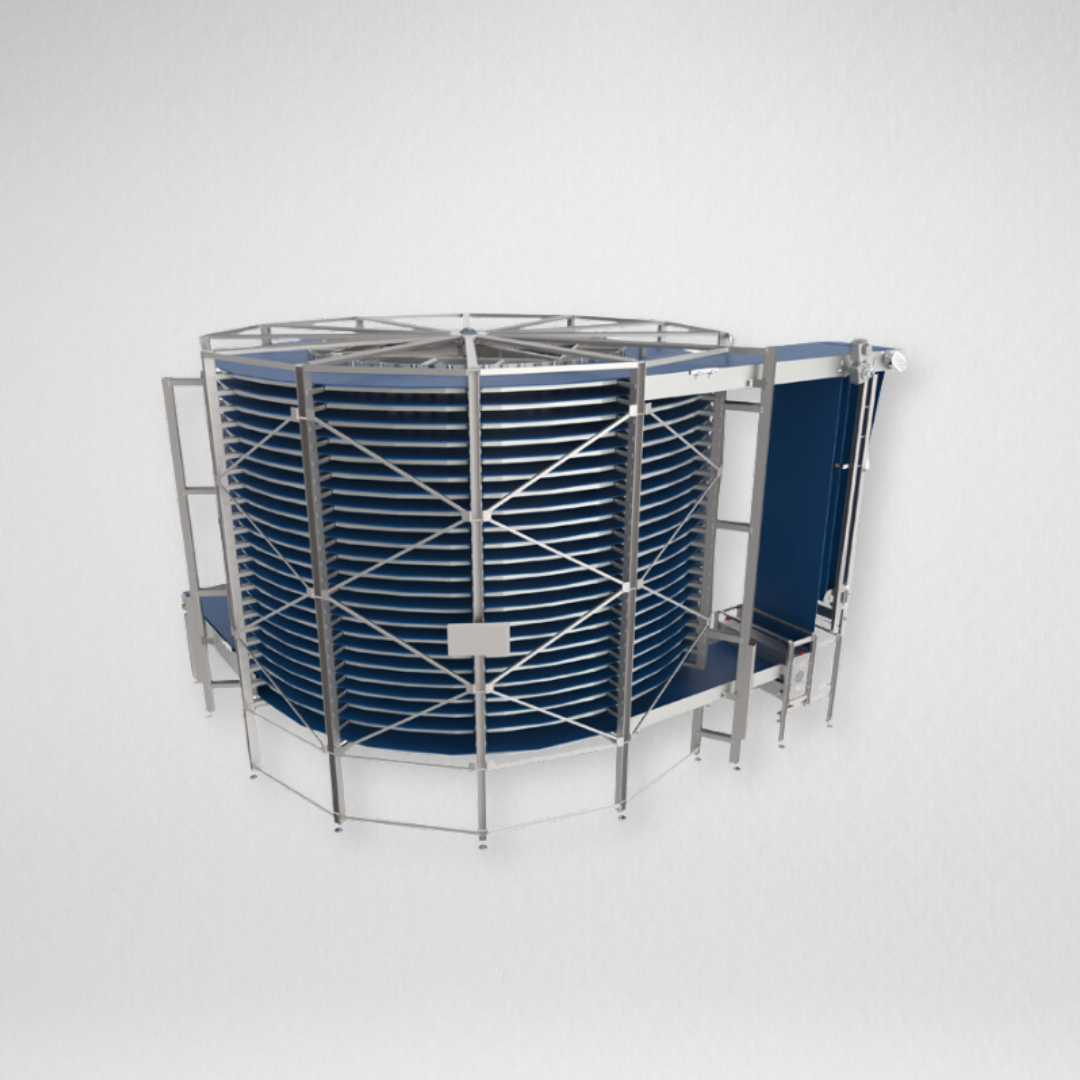

Maximize Space While Perfectly Cooling Your Bakes

After baking, flatbreads need to cool down before packaging or further processing. A spiral cooling tower offers an efficient solution using vertical space to cool large quantities of flatbreads in a smaller area.

Look for cooling systems that maintain proper airflow and temperature control to avoid condensation, which can affect the texture and shelf life of the flatbreads. The tower should also be easy to clean and maintain.

Baking Trays and Pans: The Unsung Heroes of Perfect Heat Distribution

Baking trays and pans are essential to any flatbread production setup. They ensure that the dough is supported while it bakes, contributing to even heat distribution and the shape of the finished product.

Invest in high-quality, durable trays and pans that can withstand repeated use in a commercial bakery environment. Non-stick surfaces are beneficial, especially for sticky doughs like those used for tortillas or parathas.

Work Tables and Prep Surfaces: Optimize Your Workflow with the Right Setup

Proper work tables and prep surfaces are needed for every stage of flatbread production, from mixing and dividing to sheeting and packaging. They provide the space needed to operate efficiently and maintain a hygienic environment.

Stainless steel tables are preferable for their durability and ease of cleaning. Ensure that your work surfaces are large enough to handle the production volume and strategically placed within your flatbread production setup for optimal workflow.

Tailor Your Setup for Optimal Flatbread Production

Investing in the right bakery equipment is vital for successfully producing flatbreads. Each piece of equipment, from dough mixers to spiral cooling towers, plays a role in creating high-quality products. When searching for the ideal baking equipment, consider important factors like your production needs, available space, and budget before deciding.

Ready to Elevate Your Flatbread Production?

If you're serious about optimizing your flatbread production process and want to explore the most effective solutions, it's time to take the next step. Visit our Bakery Automation page today to discover how AMI's customized equipment can transform your operations.

Real Success Stories: How AMI Equipment Transforms Bakeries

Explore how our customized solutions have helped bakeries across the industry achieve remarkable results. Click on the links below to read their full stories:

- Napoli Foods Inc.: Transforming Pizza Production with AMI Equipment's Industrial Pizza Oven

- Shaloha Pita: Innovating Mediterranean Bread Making with Custom Ovens

- Kermanig Bakery: Enhancing Efficiency with Bakery Automation Solutions

Each story showcases the impact of our bakery equipment on real businesses, from reducing labor costs to improving product consistency. Discover how you can achieve similar success with the right equipment tailored to your needs.

Share this page:

You May Also Be Interested

Site Map

AMI Equipment

Expertly crafted ovens and automation solutions for authentic, traditional flatbread production. Fully customizable and backed by lifetime support.

Follow Us:

Copyright © 2024 AMI Equipment - All Rights Reserved