Blending Tradition with Technology: How Tunnel Ovens Preserve Culinary Heritage While Boosting Efficiency

Share this page:

At first glance, bakeries using tunnel ovens might appear to snub their nose at tradition. However, tunnel ovens preserve culinary heritage while producing large batches of traditional breads. Although it might seem that using a modern tunnel oven would never stand up to traditional methods, they produce the flavors, textures, and experiences enjoyed for generations at a fraction of the cost and time.

Revolutionizing Bakery Operations with Tunnel Oven Technology

Tunnel oven technology overcomes the challenge bakeries face today, allowing you to remain faithful to heritage flavors while keeping up with growing demand. Here's how.

Historical Context of Baking Traditions

The first breads date back 30,000 years to ancient Egypt when flatbreads were produced by mixing ground grains, water and salt and "baking" them on flat rocks heated by the sun. The addition of yeast likely started between 1300 and 1500 BCE in Ancient Egypt, although there is some argument the creation of yeast for bread and beer occurred in China. Regardless of where yeast was first introduced, it is believed the original fermentation and baking methods were shared between Egypt and Babylon, made their way to ancient Greece and Jewish cultures, and eventually arrived in Rome.

The Rise of the Roman Bakery: A Communal Endeavor

Professional bakers did not start selling bread until 168 BCE in Rome. However, it was far more common to have communal bread ovens where each household made their own dough using their own method, grains, and starters and paid a fee to use the oven. The ovens were owned by either a tradesman, a local lord (most common in Europe), or the collective community, which worked by producing heat radiating from fired stone. However, it took hours to stoke the fire and warm the stones enough to bake the bread.

From Middle Eastern Flatbreads to French Loaves

The bread-baking traditions varied across different regions, with flatbread favored in areas such as the Middle East and loaves being the traditional bread in European areas such as Italy and France. France likely perfected the art of baking loaves, and eventually, the neighborhood "boulangeries" took over the tradition of the village ovens.

Preserving Flavor in the Face of Change

The process of doing everything by hand became more challenging as populations grew. This led to the industrialization of bread making, starting with mechanical mixers and eventually leading to larger commercial baking ovens. Unfortunately, the large ovens relied on heat forced through the air that took away from the flavor, texture, and appearance of what today is considered "artisanal loaves." However, advancements in tunnel oven technology have changed that.

The Role of Tunnel Ovens in Modern Baking

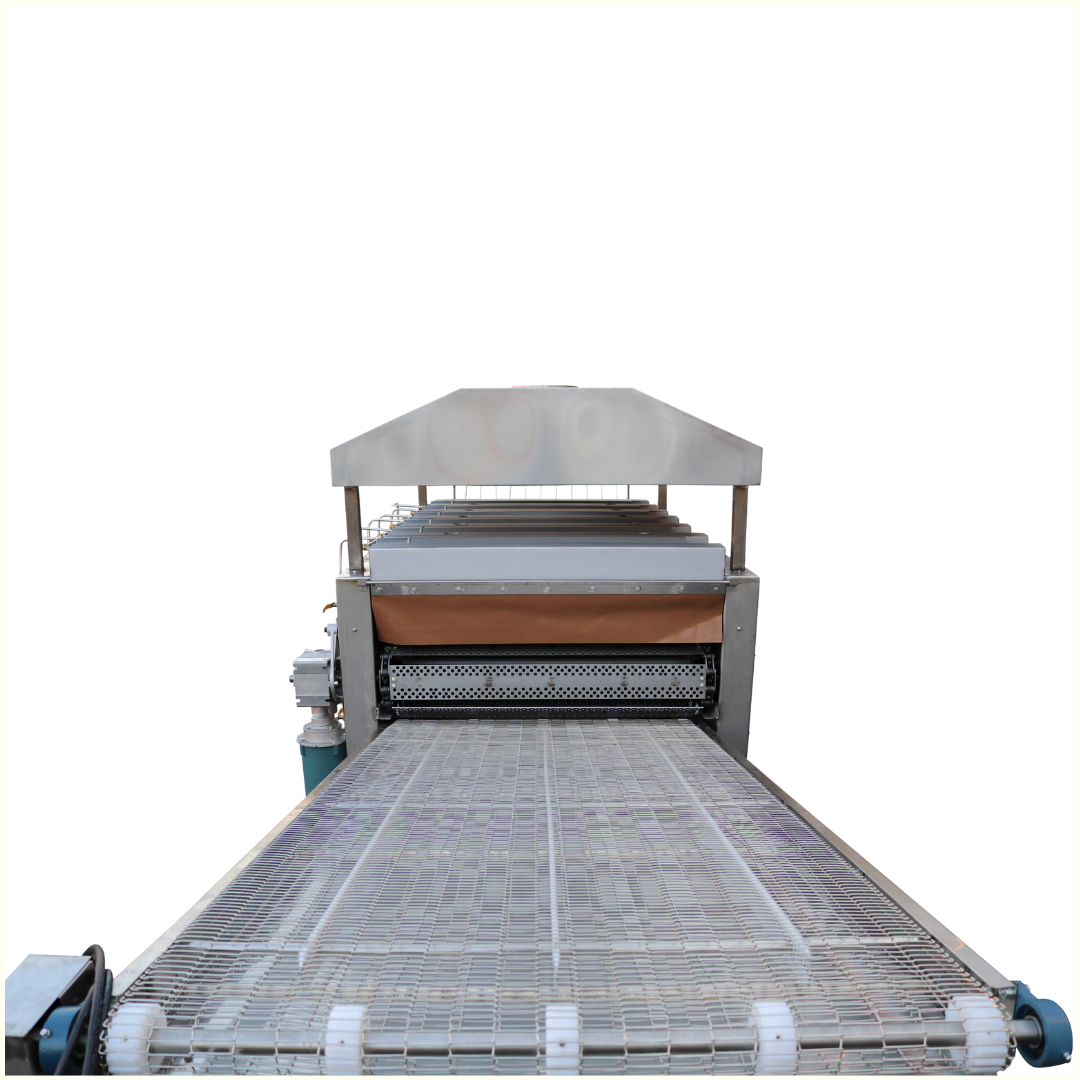

Tunnel ovens preserve the integrity of traditional baking methods, which were once only accomplished using hot stone or metal surfaces fired by wood-burning ovens. They allow you to produce thousands of flatbreads per hour without sacrificing the customer experience. This "continuous baking equipment" consists of an enclosed and thermally insulated box and a heating mechanism that is either direct gas-fired (DGF) or indirect heating. A convection system circulates the baking chamber, and products move through the "tunnel" on a conveyor belt.

Modern baking technology times the bake from the entry to the end of the baking chamber, so the product is perfect based on settings suited to the bread type. The ovens are customized with solid carbon steel plates, perforated steel plates, or Cordierite baking stones, allowing bakeries to replicate the traditional baking process without interfering with the authenticity of your product. You can also control the amount of bread you produce to meet your customers' needs.

Boosting Efficiency with Advanced Oven Technology

Advanced tunnel oven technology allows you to boost efficiency and optimize the production of high-quality products in several ways:

Automated Processes:

Once outputs become high, batch baking costs soar when workers manually prepare, knead, shape, load, and unload the product. Automation reduces labor costs by eliminating manual handling of the dough, pans, and racks while ensuring product consistency to maintain a high-quality product. Your bakers can experiment with settings and timing to develop the perfect, repeatable automatic process for consistently pleasing results in a fraction of the time of conventional methods.

Increased Production Rates:

Automation introduces continuous cooking capabilities, allowing your bakery to increase volume within the same timeframe with less labor and effort than your traditional ovens. Tunnel ovens allow for faster loading and unloading of baked goods, optimizing workflow and increasing throughput.

Energy Efficiency:

Tunnel ovens reduce energy consumption using a mix of heated surfaces and forced air circulation to bake a wide variety of baked goods quickly and evenly. Using advanced thermal controls and insulation that improve baking consistency, you can enjoy energy consumption reductions. The hot air movement working with radiant heat also lowers baking temperatures for further energy savings.

Enhanced Product Consistency:

Consistent environmental controls in tunnel ovens ensure uniform quality thanks to hot air circulation and heated surfaces. The result is a consistent bake, color, and texture. Often, consistency is sacrificed when scaling production. However, tunnel ovens give your bakers control over the quality of their product using advanced controls that allow them to customize their bakes.

Adapting Traditional Methods with Modern Equipment

Today's tunnel ovens bridge the gap between time-honored techniques and modern efficiency. Equipped with various specialized baking plates, each tailored for specific types of bread, tunnel ovens ensure that the essence of traditional flavors and techniques is maintained even as production scales up.

Here's a closer look at the types of baking plates available and how they contribute to keeping traditional baking alive:

Solid Steel Plates:

Ideal for achieving the perfect crust and texture in pita, focaccia, naan, and samoon, these plates emulate the conductive properties of ancient baking methods.

Perforated Plates:

These allow for enhanced air circulation, perfect for producing crispy, evenly-baked lavash.

Pebble Stone Plates:

Best for baking sangaack, these mimic the traditional pebbled surface, providing a unique texture and depth of flavor reminiscent of the bread's rustic origins.

Cordierite Stones:

A top choice for pizza and artisan bread, cordierite stones offer superior heat retention and distribution, ensuring a consistent artisanal finish every time.

By integrating these diverse baking surfaces into modern tunnel ovens, bakeries can continue to produce traditional breads with authentic flavors and textures, while benefiting from the efficiencies of modern technology.

Culinary Innovation Through Technology

Today, bakers can produce the "artisanal" look and heritage bread experience by using technology to achieve the perfect bake every time. Culinary innovations are easier with access to custom-made infrared burners that provide consistent and even heat distribution. You can still have that hands-on experience by experimenting with different settings and baking plates to get your desired bake and deliver a consistent, high-quality product to maintain customer loyalty.

Expand Your Bakery's Horizons Without Losing the Past

If traditional methods keep you from growth, tunnel ovens allow you to scale your operations without sacrificing flavor. They are designed to preserve your culinary traditions while boosting production, reducing labor, and providing significant cost savings.

Click here to learn more about our tunnel ovens.

Explore More Insights

Explore expert articles to enhance your baking practices and stay at the forefront of the industry.

Site Map

AMI Equipment

Expertly crafted ovens and automation solutions for authentic, traditional flatbread production. Fully customizable and backed by lifetime support.

Follow Us:

Copyright © 2024 AMI Equipment - All Rights Reserved